A perfectly built wall can be spoilt by poor finishing of the mortar joint.

In the early 1990's as a brickie foreman at the Robertson library Curtin Uni (stage 2) we were instructed by the architect to use a plastic rod instead of a steel jointer. We used the rod out of a plastic cray pot as there was nothing available in retail. They worked quite well but lost their shape quickly and we used a lot.

The reason this was specified was because a lot of brickies did not have the patience and this meant the jointing was being discolored (burning) due to leaving the joint to long and the moisture evaporating out of the face of mortar joint. The plastic jointer removed a skill set.

We all know that the lime mortar joint will erode over time. To slow down that process you create a shell of lime on the surface of the mortar joint. This done by smoothing the joint with a trowel while it contains moisture on the face.

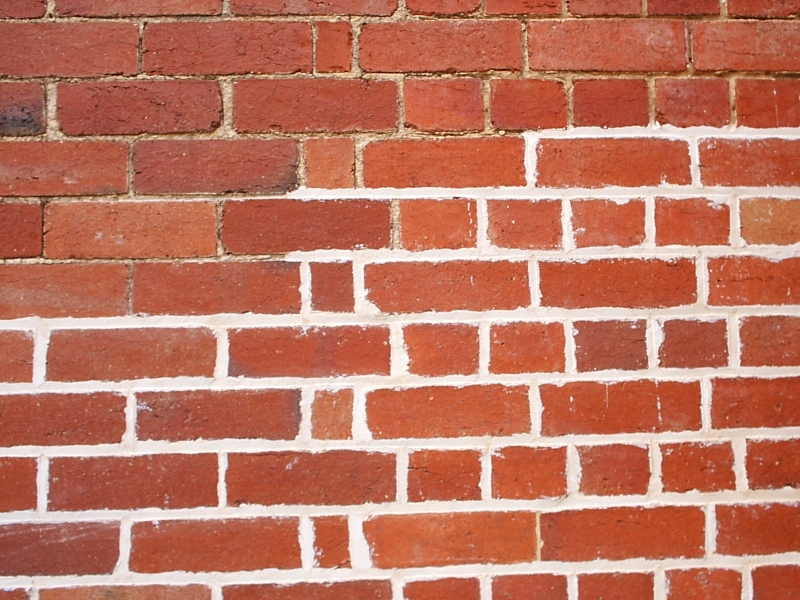

By creating that polished joint it has bought more lime to the surface thus it calcifies out bright white in colour. You can see below as the sand coloured mortar dries out to white. The building was 100 years old at the time we worked on it.

Something to note with regards to mixing lime mortar is that when it dries and is yellow in colour then there not enough lime in the mix. It should be bright white (3:1)

The steel jointer like the steel trowel must be used while the surface of the mortar joint is moist. How often you pick up the jointer is really based upon the weather. In February you may only lay 4 bricks then use a steel jointer. As opposed to the plastic one which will allow you to lay more without burning the mortar joint.

With some of the thicker plastic jointers used on the bricks below they will bump along joint due to the bumpy arris of the brick. There will be excessive mortar still clinging to the top and bottom edge of the mortar joint. Leave that in place for a while and use a very soft broom to brush them off.

Burning the mortar joint is the black mark left by the steel due to the lack of moisture in the mortar. Wetting the bricks before laying them is common. For feature work the polished face leaves a nice finish. This is a 12 mm stainless steel jointer onto a 10 mm joint which creates the traditional concave.